The Financial Benefits of Regular strapping machine service

Open Optimum Performance With Comprehensive Strapping Machine Service and Upkeep

Strapping machines play an essential function in product packaging procedures. Their performance directly affects productivity and effectiveness. However, lots of services overlook the value of routine solution and upkeep. This oversight can result in increased downtime and higher repair expenses. Comprehending the crucial advantages of a proactive maintenance strategy is vital. As companies seek to boost their operations, discovering comprehensive treatment alternatives comes to be needed. What steps can be required to assure peak efficiency?

The Value of Routine Maintenance for Strapping Machines

Secret Benefits of a Proactive Upkeep Approach

A positive maintenance approach supplies substantial benefits for strapping machines - strapping machine service. By prioritizing regular maintenance, companies can attain enhanced tools longevity, improve operational performance, and decrease threats connected with downtime. These advantages add to a more trustworthy and productive product packaging process

Boosted Equipment Durability

Executing an aggressive upkeep technique substantially enhances the longevity of strapping machines. By routinely servicing and checking devices, potential issues can be recognized and attended to before they intensify right into expensive repair work or failures. This strategy minimizes damage, ensuring that all elements operate efficiently with time. Furthermore, routine maintenance helps preserve the integrity of critical components, minimizing the chance of unforeseen failures. Consequently, businesses can extend the operational life-span of their strapping machines, maximizing their financial investment. In addition, well-maintained equipment is less prone to sudden breakdowns, permitting a much more stable manufacturing atmosphere. Eventually, a commitment to positive maintenance not only maintains tools long life but additionally cultivates integrity and consistency in packaging procedures.

Boosted Functional Effectiveness

They usually experience significant improvements in operational performance when businesses focus on aggressive upkeep for strapping machines. This technique warranties that devices operates at peak efficiency levels, reducing the likelihood of unforeseen issues that interfere with workflow. Consistently arranged maintenance enables timely identification and rectification of possible troubles, bring about smoother procedures. In addition, properly maintained machines require much less power and source intake, adding to total price financial savings. By assuring that strapping machines are constantly in leading problem, organizations can boost throughput, enhance item top quality, and boost employee efficiency. Eventually, this proactive technique fosters a more streamlined operation, allowing firms to meet consumer demands efficiently and preserve an affordable edge in the marketplace.

Minimized Downtime Risks

Positive upkeep noticeably minimizes the threats of downtime connected with strapping machines. By consistently servicing and inspecting equipment, possible concerns can be identified and dealt with prior to they intensify into essential failures. This method reduces unforeseen break downs, making certain that production routines stay nonstop. Additionally, with a well-kept strapping device, drivers experience boosted reliability and performance, which adds to general functional connection. Set up maintenance likewise permits for the efficient use of sources, reducing the requirement for emergency situation fixings that can be costly and taxing. Consequently, businesses gain from boosted performance and a much more structured workflow. Ultimately, purchasing positive maintenance results in a significant reduction in downtime dangers, fostering an extra resilient manufacturing atmosphere.

Usual Concerns That Develop From Overlooking Upkeep

Neglecting maintenance on strapping machines can lead to a myriad of problems that inevitably interrupt procedures. One typical problem is the accumulation of dust and particles, which can cause mechanical parts to jam or use out prematurely. In addition, failure to oil moving elements might cause enhanced rubbing, leading to getting too hot and possible break downs. Misalignment of parts frequently happens without regular modifications, causing poor strapping top quality and lost materials. Electric elements can deteriorate if not evaluated frequently, resulting in irregular performance or total failure. These concerns not only compromise manufacturing performance but likewise increase fixing expenses, highlighting the significance of constant upkeep to ensure peak equipment performance and longevity.

Specialist Care: Just How Expert Solutions Enhance Tools Durability

Specialist solutions play an essential role in expanding the life expectancy of strapping machines via browse around this site targeted maintenance approaches. strapping machine service. By applying preventative procedures, these specialists not only decrease the probability of equipment failure but also boost overall functional performance. In addition, their troubleshooting methods enable speedy identification and resolution of problems, guaranteeing machines remain in peak problem

Prolonging Tools Life-span

Preventative Maintenance Benefits

Preventative upkeep uses significant advantages for the durability and effectiveness of strapping machines. By applying normal inspections and maintenance, operators can determine potential issues before they escalate right into expensive failings. This positive strategy not only prolongs the life expectancy of the equipment yet likewise boosts its performance, making certain reputable and consistent operation. In addition, preventative upkeep minimizes downtime, enabling businesses to maintain productivity while reducing repair work prices related to emergency failures. Expert services offer expertise in keeping optimal equipment problems, utilizing specialized knowledge to address particular deterioration. Eventually, purchasing preventative upkeep safeguards tools integrity, promotes functional performance, and supports a more sustainable service design, adding to overall cost financial savings and enhanced profitability.

Professional Troubleshooting Methods

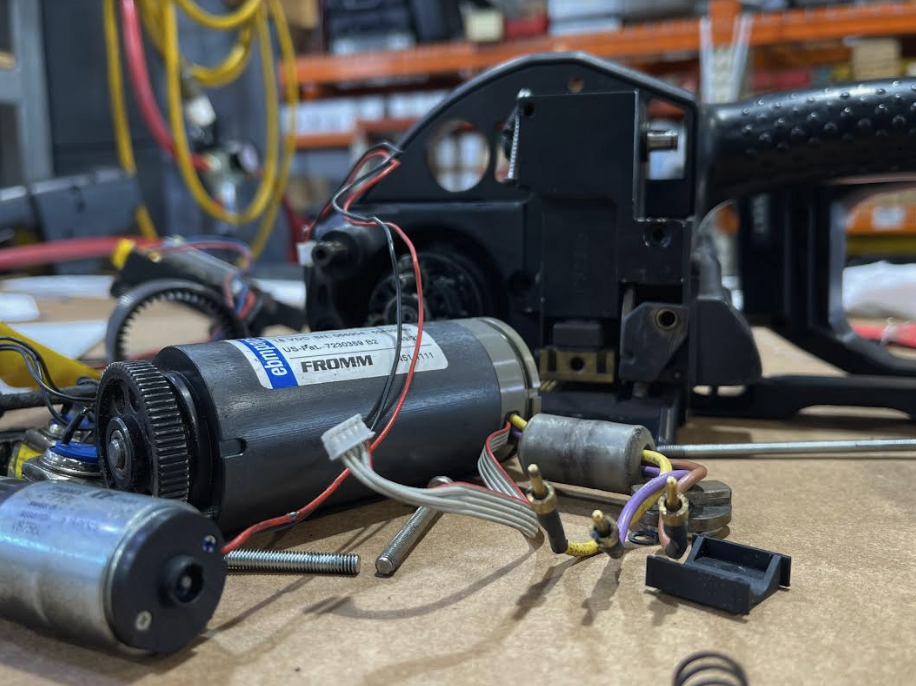

Reliable repairing techniques are crucial for dealing with unforeseen issues that can occur throughout the procedure of strapping machines. Professionals trained in these strategies utilize systematic approaches to identify and fix problems efficiently. They start by assessing error codes and device efficiency information, which helps limit possible mistake areas. Next off, they inspect components, such as sensing units, belts, and motors, to detect wear or misalignment. Making use of sophisticated diagnostic devices, they can pinpoint issues that might not be instantly visible. Additionally, their expertise enables them to recommend rehabilitative actions, guaranteeing very little downtime. By using these specialist fixing strategies, drivers can improve equipment longevity and preserve peak performance, inevitably bring about raised productivity and minimized functional costs.

Creating a Custom-made Maintenance Arrange

A well-structured useful link maintenance timetable is vital for making sure the ideal performance and long life of strapping machines. To establish a tailored schedule, drivers need to first evaluate the device's usage patterns, recognizing high-demand durations and potential anxiety points. Routine assessments must be scheduled based on producer recommendations, while likewise taking into consideration real functional problems. Key tasks may consist of cleaning, lubrication, and components substitute, customized to the particular version and application. In addition, recording maintenance activities permits trend analysis, helping to anticipate future requirements and minimize downtime. Involving with solution specialists can give understandings into ideal methods and essential changes, making sure that the upkeep timetable advances alongside the machine's efficiency and operational demands. This positive method ultimately boosts efficiency and integrity.

Purchasing Educating for In-House Maintenance Teams

Educating programs for in-house maintenance interplay a vital duty in taking full advantage of the efficiency and reliability of strapping machines. By outfitting team members with specialized abilities, organizations can ensure that maintenance and troubleshooting are performed effectively and immediately. Knowledgeable personnel can identify potential issues prior to they escalate, reducing downtime and maintenance expenses. In addition, training cultivates a much deeper understanding of the equipment, allowing groups to carry out finest techniques for operation and treatment. This investment not only improves the performance of strapping machines however likewise enhances team morale and self-confidence, bring about a more positive upkeep culture. Ultimately, prioritizing training will certainly produce substantial long-term advantages, ensuring peak efficiency and extending the lifespan of strapping devices.

Often Asked Questions

Exactly How Usually Should Strapping Machines Be Serviced?

Strapping machines should usually be serviced every six months to assure peak efficiency. Regular upkeep checks help recognize issues early, extend the equipment's life-span, and keep regular strapping quality and effectiveness in manufacturing processes.

What Are the Indications That Maintenance Is Needed?

Indications that upkeep is required include unusual sounds, irregular strapping high quality, frequent jams, mistake messages on the display screen, and noticeable wear on parts (strapping machine service). Resolving these concerns quickly can prevent more damage and guarantee reliable operation

Can I Do Maintenance Without Specialist Assist?

Yes, individuals can perform standard upkeep on tools, such as cleansing and examining components. Nevertheless, for complex problems, professional aid is advised to assure safety and security and proper functioning, stopping potential damage or functional failures.

What Components Commonly Need Substitute During Servicing?

Throughout servicing, commonly changed parts consist of belts, springtimes, sensors, and blades. Regular evaluation of these elements assurances peak performance and prolongs the life-span of strapping machines, avoiding unanticipated break downs and boosting overall performance.

Exactly How Can I Track My Machine's Maintenance History?

To track a machine's upkeep background, one can utilize logbooks, electronic monitoring software, or upkeep monitoring systems that tape service dates, carried out jobs, and changed parts, guaranteeing extensive oversight of the device's functional problem.

Applying a positive upkeep technique significantly enhances the long life of strapping machines. Ignoring upkeep on strapping machines can lead to a myriad of problems that ultimately interfere with procedures. Preventative maintenance uses considerable advantages for the durability and effectiveness of strapping machines. A well-structured maintenance timetable is vital for making sure the ideal performance and long life of strapping machines. Educating programs for internal maintenance teams play an essential duty in making the most of the efficiency and dependability of strapping machines.